If you want your disc to stand out, you should consider a quality disc face printing. If you decide to print it personally, your choice should focus on three things – quality, cost and the available time. Instead of investing in expensive printing equipment, you can consider professional CD, DVD, Blu-Ray Replication and Production services.

If you consider such services, you will surely save money and if you need more items, they can consider manufacturing bulk discs in just a few days. More importantly, you will be assured of the printing quality. Before you commit, it is imperative that you know your printing options first so you can understand the service. Here are your disc face printing options:

Silk-screen printing method

You must know that silk-screen is the most common process for printing on replicated discs. This is the case because silk-screen is best for irregular surfaces like CDs, DVDs, and Blu-Rays. It can even be used on cloth products like t-shirts, beddings and table skirts. This technique utilises the CMYK (Cyan, Magenta, Yellow, and Black) color model.

To print the negative films, the disc face artwork is used. The films will then be utilised to transfer the image to the screen, which will be mounted to the press. As soon as the screens are covered with ink, there will be a rubber squeegee that will push the color through the disc surface. One of the advantages of silk-screen is it prints at 120 lpi (lines per inch). Aside from that, it is also scratch and water resistant with an increased turnaround time

Offset printing method

Offset printing, on the other hand, uses a different method of printing. There will be a set of plates created – either by film or etched directly. As soon as it is attached to the press, the plates will roll over on an inkpad, which can pick up the proper color. The plates will then roll over the disc thus applying the ink.

Offset printing offers more control over the detail and color of the artwork because images can be printed for up to 175 lpi. Moreover, the ink can be applied at thinner coats, which gives the disc a finer or smoother feel. This disc is also scratch and water resistant.

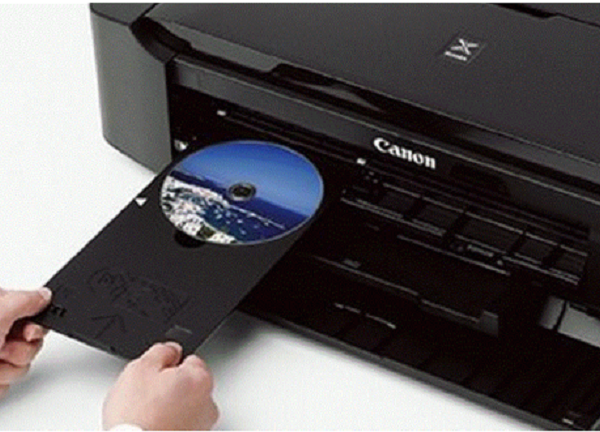

Inkjet printing method

Inkjet is a printer that provides up to 2400-4800 dpi (dots per inch) resolution on discs. Individual discs are directed to the printer, which can be dried in 20 seconds to 2 minutes. However, it does not provide the same look and feel compared to silk-screen or offset printing. Inkjet instead offers quantity, flexibility and faster turnaround time.

Without a doubt, ordering disc printing frees up your time and energy. Through this, you can focus more on your music. By employing the help of suppliers, you will be offered packaging options, price and other programs that make it more affordable for you.

With this, you need to find a reliable supplier like http://implant.com.au/ that will make a quality product at a fair price. As you know now, there are so many options out there that can help you sell your merchandise. At the end of the day, what matters most is the content.