When it comes to producing products, the product developers follow different methods to make the perfect parts. For this concern, they wish to use the prototyping method to optimize the design process of parts. The prototype injection moldingis really better for building prototype mold. It is regarded as the best and effective manufacturing process today. The product designers need to use this process for making the high quality and fine parts in large numbers. You can make a large number of products with the effective use of the molding technique. You can spend only quite amount of money for using best tooling for production.

Prototype production acts as an essential solution for the final process of the product. You can go for the best type of prototype production. It is very essential for manufacturing companies to produce different parts into multiple copies by spending only less amount of money. You can make sure the large scale production in the manufacturing companies. You can get the right product and keep up the perfect prototype very handy. You can ensure the mass production process with the injection molding. It is a great option to get a perfect prototype part with the ideal manufacturing tool.

Run the parts effectively:

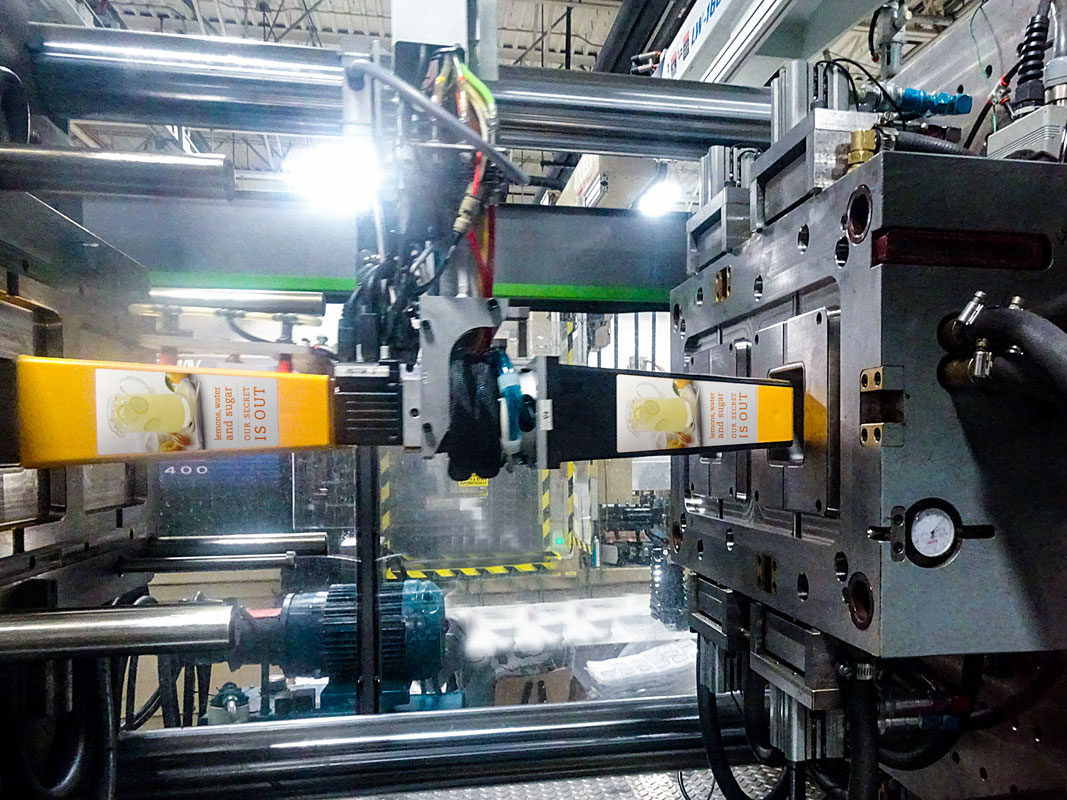

It lets the product designer to produce the products quickly and fairly. Apart from this, you can run the produced parts with the injection molding technique with the specific materials. It is better for engineers to evaluate the fit, form, and function of the parts. You can establish the mold design for the molding optimization. It helps you to do the functional testing more accurate and fine and give the ideal date for the development and design of the product. You can choose right type of prototype injection molding that better for production enhancement in the company. The product designers can eliminate the potential risk involved in the product production. This process helps you to achieve a great success in the product production. This will assure the mass production that best for the industry. You can use the right method and gain the good result as soon as possible. You can select the right material that better to resist wear and tear.

Get the perfect volume of products:

The service provider recommends the best parts for different volumes like low, medium, and high volume. You can follow the right ways to assure the perfect quality and excellent finish of the products. It is a better option to meet the large volume capacity and minimizes labor cost. It is the best method for optimizing the mold design. It is a cost effective process that ideal for designing perfect part simply. In this way, designers can achieve bulk production in a quick manner. It provides stunning benefits to manufacturing companies to produce different array of parts within a single shot. You can get ready for the next process of the product design without wasting time. It is a great solution to reduce mechanism of molding and develop parts easily.